Introduction to Cold Spray Process

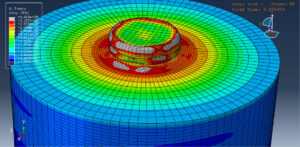

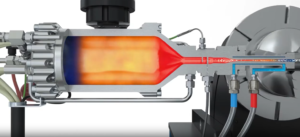

The cold spray process is an advanced additive manufacturing and coating technology that involves the deposition of solid powder particles onto a substrate at high velocities but relatively low temperatures. Unlike traditional thermal spray methods, which often involve melting or significant heating of the feedstock material, cold spray relies on kinetic energy rather than thermal energy to create a bond between the particles and the substrate. Abaqus is a powerful finite element analysis (FEA) software widely used for simulating complex mechanical, thermal, and multiphysics problems. When it comes to modeling the cold spray process, Abaqus provides a robust platform to analyze the impact, deformation, and bonding of particles during deposition. By leveraging Abaqus’s advanced capabilities, researchers and engineers can gain insights into the cold spray process, optimize parameters, and predict the mechanical behavior of deposited coatings or structures

Key Aspects of Cold Spray Simulation in Abaqus

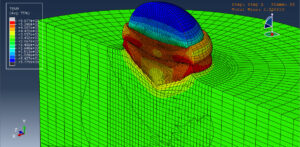

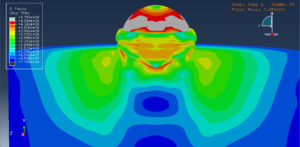

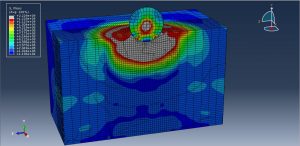

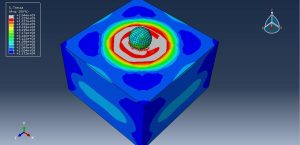

Particle-Substrate Interaction

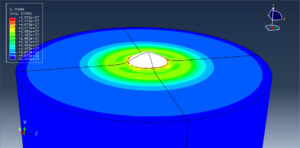

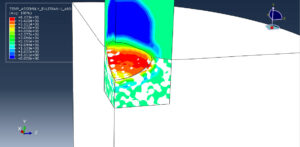

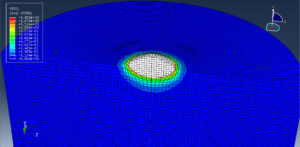

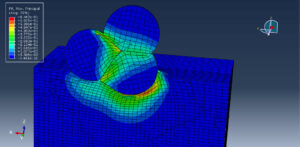

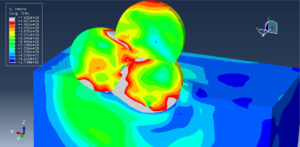

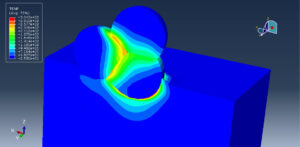

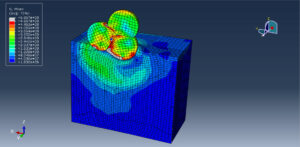

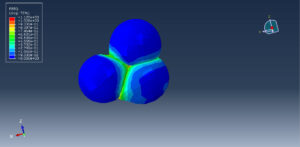

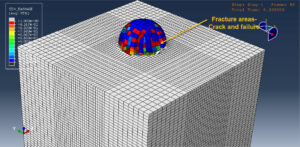

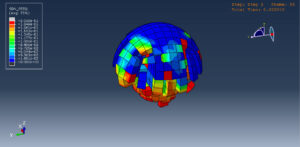

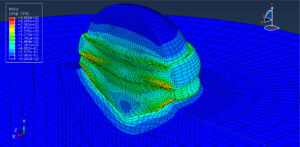

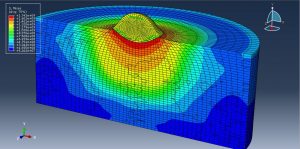

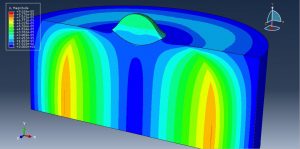

Abaqus allows for the simulation of high-velocity particle impact on a substrate, capturing the plastic deformation, stress distribution, and bonding mechanisms

The explicit dynamics solver in Abaqus is typically used to model the high-speed impact and transient behavior of particles

Material Modeling

Abaqus supports a wide range of material models, including elastic-plastic, viscoplastic, and strain-rate-dependent models, which are essential for accurately representing the behavior of cold spray materials

Material properties such as yield strength, hardening behavior, and strain-rate sensitivity can be defined to match experimental data

Contact and Bonding

Abaqus provides advanced contact algorithms to simulate the interaction between particles and the substrate

Bonding mechanisms, such as mechanical interlocking and metallurgical bonding, can be modeled using cohesive zone models or user-defined subroutines.

Thermal Effects

While the cold spray is primarily a solid-state process, Abaqus can also incorporate thermal effects if needed, such as heat generation due to plastic deformation or preheating of the substrate

Advantages of Cold Spray

Low Thermal Impact: Since the process operates at low temperatures, it minimizes thermal stress, oxidation, and phase changes in the feedstock material

Wide Material Compatibility: Suitable for a variety of materials, including metals, alloys, composites, and even ceramics

High Deposition Efficiency: Minimal material waste compared to other thermal spray techniques

Restoration and Repair: Ideal for repairing damaged components, such as aerospace parts, without compromising their structural integrity

Additive Manufacturing: Can be used to fabricate near-net-shape components or add features to existing parts

Applications of Cold Spray Simulation in Abaqus

Process Optimization: Study the effects of process parameters to achieve optimal deposition quality

Coating Design: Predict the mechanical properties and performance of cold spray coatings

Failure Analysis: Investigate potential failure modes, such as delamination or cracking, under mechanical or thermal loading

Research and Development: Explore new materials or bonding mechanisms for cold applications

Simulating the cold spray process in Abaqus offers a powerful way to understand and optimize this advanced manufacturing technique. By leveraging Abaqus’s capabilities, engineers and researchers can gain valuable insights into the mechanics of particle deposition, improve coating quality, and reduce the need for costly experimental trials. As cold spray technology continues to evolve, Abaqus will remain a critical tool for advancing its applications across industries.

In this package, you will learn all types of Cold Spray modeling, including all materials and methods

The package contains Nine separate tutorials, each tutorial includes cae, inp, code, paper, reference of the materials, and step-by-step English video. You can check the titles of the tutorials below

A) Simulation of the Cold Spray process of an ABS material by using the CEL method in Abaqus

B) Simulation of Depositing Al-Based Metallic Coatings onto Polymer Substrates by Cold Spray in Abaqus

C) Simulation cold spray process of a ceramic particle on the steel material in Abaqus

D) Simulation deposition behavior of multi-particle impact in cold spraying process in Abaqus

E) Simulation cold spray process of steel particles on the Inconel surface by using the ALE method in Abaqus

F) Simulation cold spray process of ceramic particles impact on to the titanium target in Abaqus

G) Simulation cold spray process by using the SPH method in Abaqus

H) Simulation Cold Spray process in Abaqus by using the ALE method

I) Simulation of the Cold Spray Particle Deposition Process in Abaqus by using the CEL method

The price of this package is Seventy-Six Euros, you can use a PayPal account, a Visa, or a Mastercard for the payment.

If you are interested in the fire package, send us an email here: abaqusfem.com@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials