Introduction to Ceramic and Silicon Carbide Materials

Ceramics are inorganic, non-metallic materials known for their high hardness, thermal stability, and chemical resistance. They are typically made by heating natural minerals (like clay) or synthetic powders at high temperatures (sintering). Silicon carbide is an advanced ceramic and semiconductor material composed of silicon and carbon. It occurs naturally as Moissanite but is commonly synthesized for industrial use

Applications

Structural ceramics (e.g., alumina, zirconia) for cutting tools, bearings, and biomedical implants

Refractory ceramics for furnace linings

Electronic ceramics (e.g., piezoelectrics, insulators)

Abrasive & Cutting Tools: Grinding wheels, sandpapers

Refractories: High-temperature furnace components

Electronics: Power electronics, LEDs, and high-voltage devices (due to their semiconductor properties)

Armor & Aerospace: Bulletproof vests, spacecraft components

Automotive: Brake discs, ceramic matrix composites (CMCs)

Introduction to Ceramic and Silicon Carbide (SiC) Modeling in Abaqus

Abaqus is a powerful finite element analysis (FEA) software used for simulating the mechanical, thermal, and multiphysics behavior of materials, including ceramics and silicon carbide (SiC). These materials are widely used in high-temperature, structural, and wear-resistant applications, but their brittle nature and complex failure mechanisms require careful modeling approaches

Key Properties Affecting Abaqus Modeling

Ceramics in Abaqus

Brittle Fracture: Ceramics fail catastrophically with little plastic deformation

High Compressive Strength, Low Tensile Strength: Requires accurate damage models

Temperature Sensitivity: Thermal expansion and conductivity must be considered in coupled thermo-mechanical analyses

Silicon Carbide (SiC) in Abaqus

Extreme Hardness & Wear Resistance: Important for tribology simulations

High Thermal Conductivity: Useful in heat dissipation applications

Semiconductor Properties: Can be modeled in coupled electro-thermo-mechanical analyses

Material Models for Ceramics & SiC in Abaqus

Elastic Behavior

Young’s modulus (E) and Poisson’s ratio (ν)

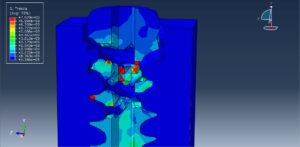

Plasticity & Damage Models

Since ceramics and SiC are brittle, plasticity is often ignored, but damage mechanics are critical

Brittle Cracking Model (Brittle Cracking)

Johnson-Holmquist (JH-II) Model

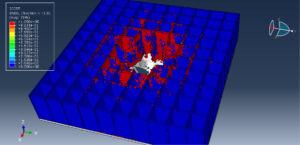

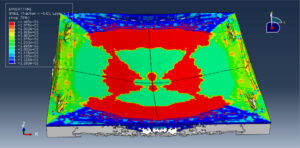

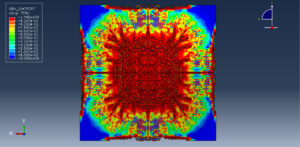

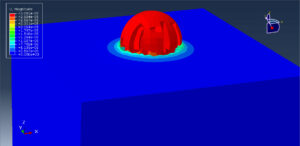

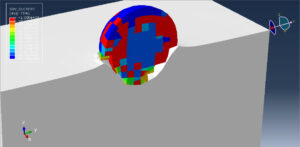

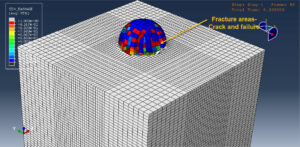

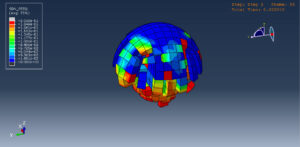

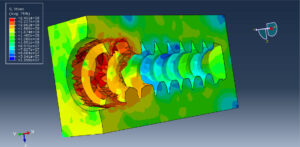

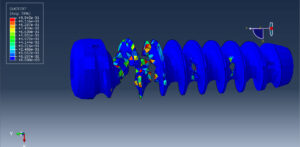

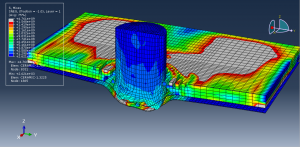

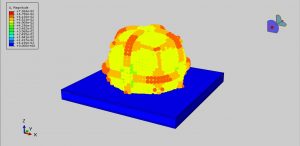

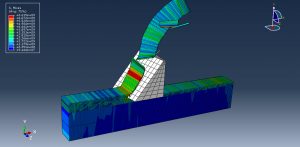

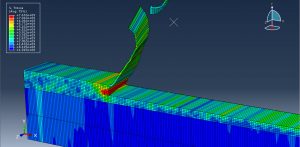

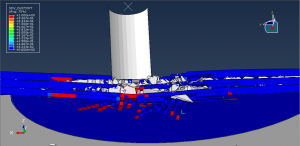

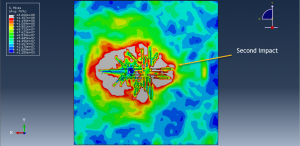

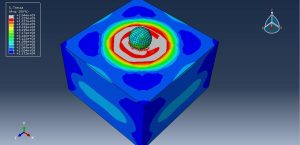

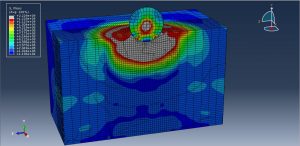

The Johnson-Holmquist (JH-II) and Johnson-Holmquist-Beissel (JHB) models are constitutive models used in Abaqus to simulate the high-strain-rate behavior of brittle materials, such as ceramics (e.g., silicon carbide, alumina, glass) and some composites. These models account for strength degradation, damage accumulation, and pressure-dependent yielding, making them ideal for impact, penetration, and blast simulations

Johnson-Holmquist (JH-II) Model

Developed for ceramics and brittle materials under dynamic loading (e.g., ballistic impact, armor penetration)

Incorporates strength degradation due to damage (progressive failure)

Uses a piecewise strength model (intact vs. fractured states)

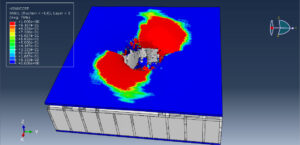

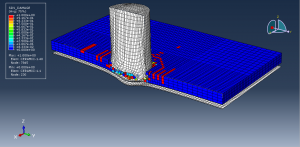

Johnson-Holmquist-Beissel (JHB) Model

An extension of JH-II with improved tensile failure and bulking effects

Better for high-velocity impact where material pulverization occurs

Includes porosity effects (compaction under high pressure)

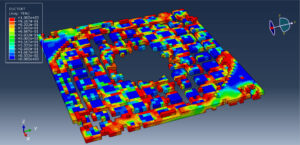

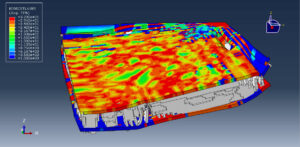

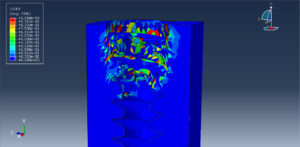

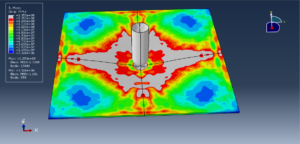

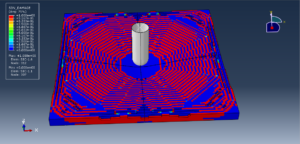

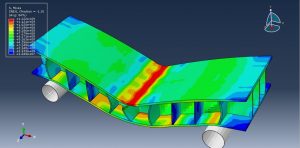

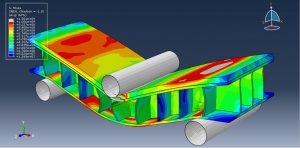

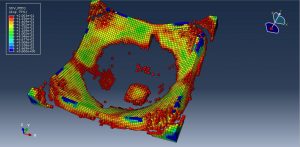

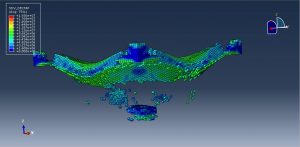

Common Abaqus Simulations for Ceramics & SiC

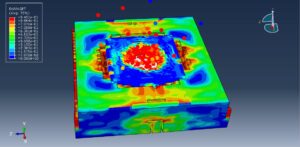

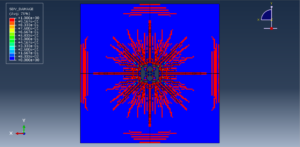

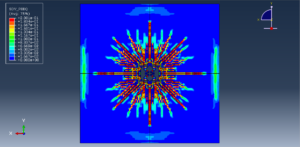

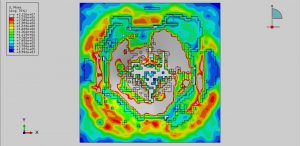

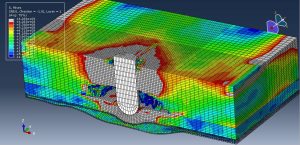

Stress-Strain & Fracture Analysis

Static/Quasi-static loading (e.g., bending, tensile tests)

Submodeling techniques to capture crack propagation

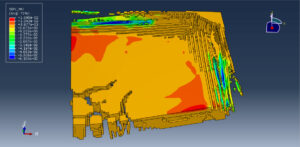

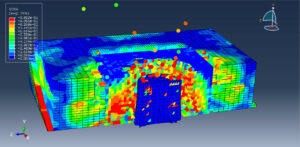

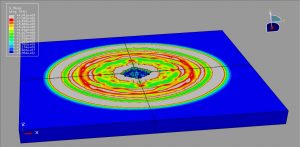

Thermal Stress Analysis

Coupled temperature-displacement analysis for thermal shock

Example: SiC heating elements in furnaces

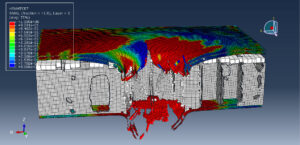

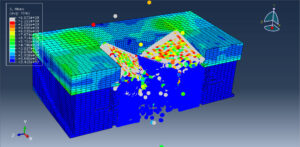

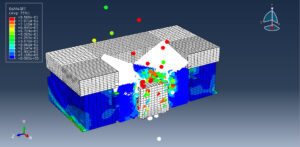

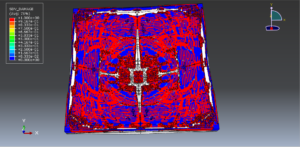

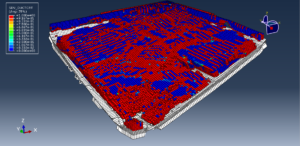

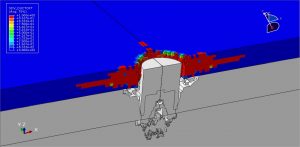

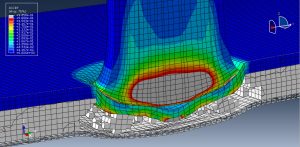

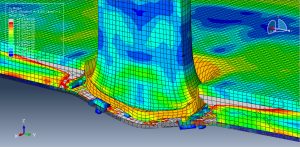

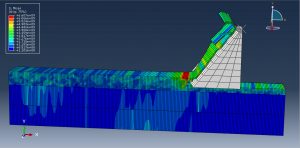

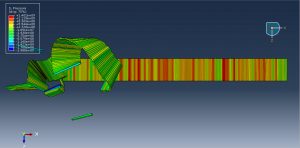

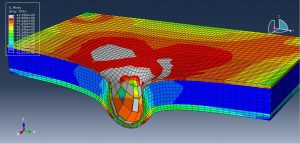

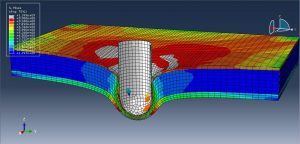

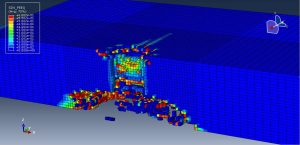

Impact & Ballistic Simulations

Explicit Dynamics (Abaqus/Explicit) for high-speed impact

JH-2 or Drucker-Prager models for fragmentation

Wear & Tribology (SiC in Abrasive Environments)

Archard’s wear law in user subroutines (UMESHMOTION)

Multiphysics (SiC in Electronics)

Piezoelectric or semiconductor behavior (requires user-defined fields)

Challenges in Modeling Ceramics & SiC

Mesh Sensitivity: Brittle fracture requires fine meshing and cohesive elements

Convergence Issues: Implicit solvers may struggle with crack propagation; explicit methods may be needed

Material Calibration: Experimental data (e.g., fracture toughness) is essential for accurate models

Abaqus provides robust tools for simulating ceramics and SiC, but their brittle behavior requires careful selection of material models (e.g., Brittle Cracking, JH-II) and solvers (Standard/Explicit). Thermal, mechanical, and multiphysics simulations are common, but validation with experimental data is crucial

JH-II is ideal for general ceramic impact simulations (e.g., armor, projectile penetration)

JHB improves accuracy for high fragmentation & bulking (e.g., hypervelocity impacts)

Both models require careful parameter calibration from experiments or literature

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials