Introduction to Bolt Analysis in Abaqus

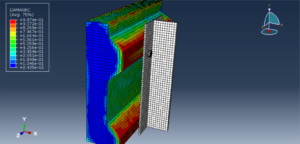

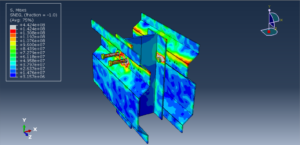

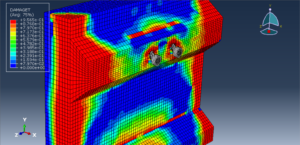

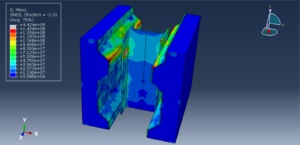

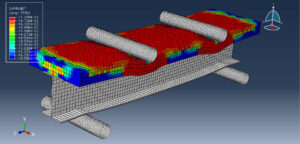

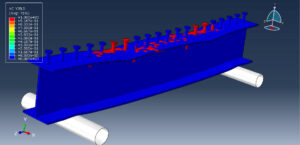

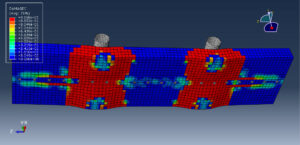

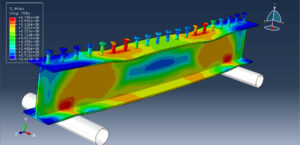

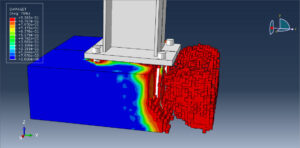

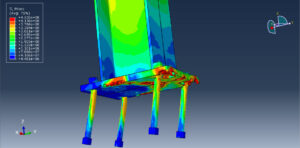

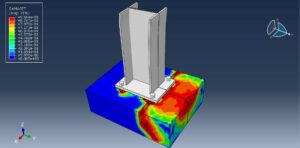

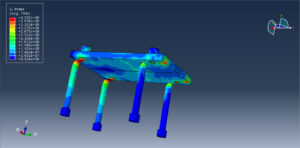

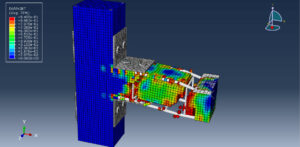

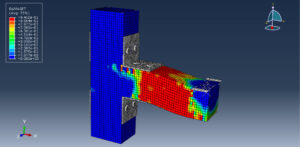

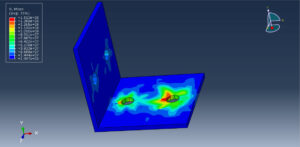

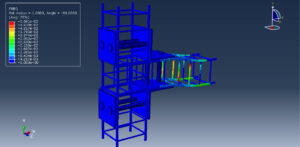

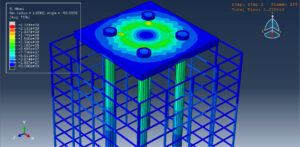

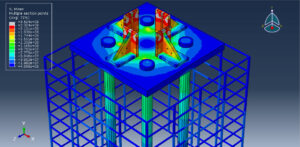

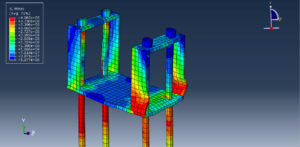

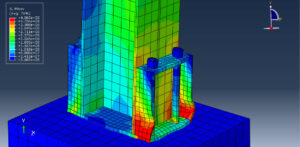

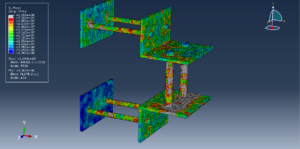

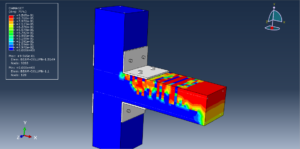

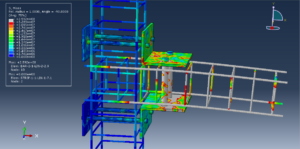

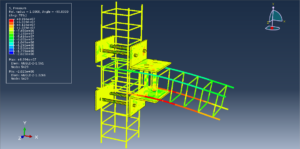

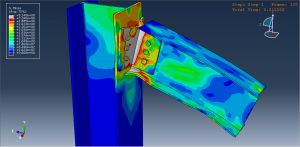

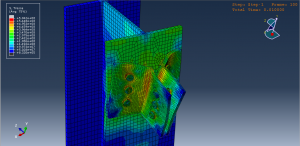

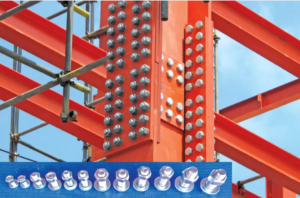

Abaqus is a powerful finite element analysis (FEA) software widely used for simulating complex mechanical systems, including bolted joints. Bolt analysis in Abaqus involves modeling the bolt, applying preload, and simulating the behavior of the bolted joint under various loading conditions. This analysis helps engineers understand stress distribution, deformation, and potential failure modes in bolted connections, ensuring the safety and reliability of mechanical assemblies. Bolts are critical components in mechanical assemblies, providing the necessary clamping force to hold parts together. Simulating bolts using the Finite Element Method (FEM) is essential for understanding their behavior under various loading conditions, such as tension, shear, and combined loads. FEM allows engineers to predict stress distribution, deformation, and potential failure points in bolted joints, ensuring the safety and reliability of the assembly

Key Aspects of Bolt Simulation Using FEM

Modeling the Bolt and Assembly

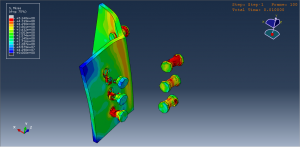

The bolt, nut, and surrounding components are modeled in 3D. Simplifications such as ignoring threads or using axisymmetric models, can reduce computational cost

Material Properties: The material properties of the bolt (e.g., Young’s modulus, Poisson’s ratio, yield strength) and the clamped parts are defined

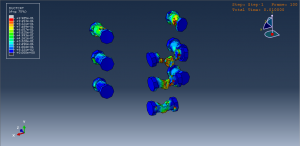

Contact Interactions: Contact conditions between the bolt head, nut, and clamped parts are modeled to simulate the interaction and load transfer

Preload Application

Preload Definition: The bolt is preloaded to a specific tension to ensure a secure joint. This preload is applied as an initial condition in the simulation

Preload Methods: Common methods include applying a tensile force, using a thermal expansion analogy, or specifying an initial strain

Analysis Types

Static Analysis: Used to determine the stress and deformation under steady loads

Dynamic Analysis: Used to study the response under time-varying loads, such as impact or vibration

Fatigue Analysis: Used to predict the life of the bolt under cyclic loading

Challenges in Bolt Simulation

Contact Nonlinearity: The contact between the bolt and the clamped parts introduces nonlinearity, making the simulation more complex and computationally intensive

Thread Modeling: Accurately modeling the threads can be challenging due to their complex geometry and the need for a fine mesh

Preload Accuracy: Applying the correct preload and ensuring it is maintained under external loads is critical for accurate simulation results

Contact Interactions

Contact Pairs: Define contact interactions between the bolt head, nut, and the clamped parts. Abaqus provides various contact formulations, such as surface-to-surface contact and node-to-surface contact

Friction: Specify the coefficient of friction between the contacting surfaces to accurately model the frictional forces

Applications

Aerospace: Ensuring the integrity of bolted joints in aircraft structures

Automotive: Analyzing bolted connections in engine components and chassis

Civil Engineering: Evaluating the performance of bolted connections in steel structures

Mechanical Design: Optimizing bolted joints in machinery and equipment

The conclusion from the above statements

Bolt analysis in Abaqus is a comprehensive approach to understanding the behavior of bolted joints under various loading conditions. By accurately modeling the bolt, applying appropriate boundary conditions and loads, and interpreting the results, engineers can ensure the reliability and safety of mechanical assemblies. Despite the challenges, Abaqus provides robust tools and features to perform detailed and accurate bolt analysis, making it an invaluable tool in engineering design and analysis.

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials