This tutorial presents a numerical analysis of the resistance and stiffness of an aluminium-concrete beam with steel connectors. Aluminium-concrete structures are less known than steel and concrete composite structures, they do, however, have a lot of applications.Contemporary designers should look for new solutions supporting sustainable construction.Aluminium-concrete composite structures have a lot of applications thanks to the corrosion-resistance and lightness of the aluminium beam.They may be used in composite bridges and in structures which are difficult to access or are located in corrosive or humid environments

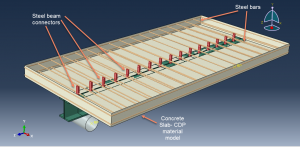

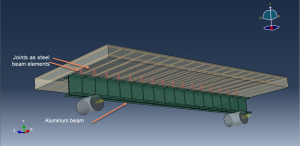

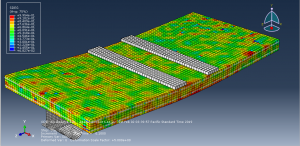

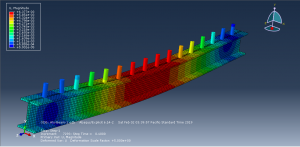

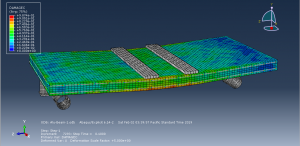

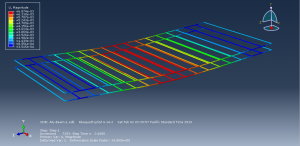

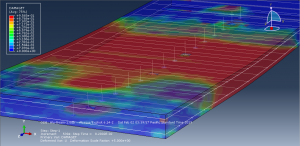

Multiple problems inherent in aluminium-concrete structures remain to be solved. Numerical calculations may be a good alternative to laboratory tests, but only if the numerical model is verified.It consisted of an aluminium beam, steel shear connectors.The concrete slab was divided into eight-node cuboidal finite solid elements, meshes were modelled by means of truss elements, shear connectors were presented as beams and an aluminium beam was divided into four-node shell elements.You can see figures about the positions at below

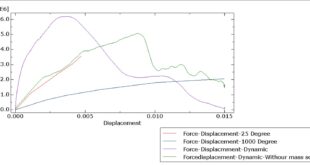

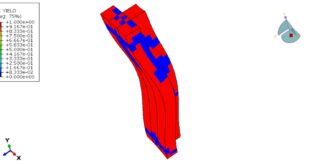

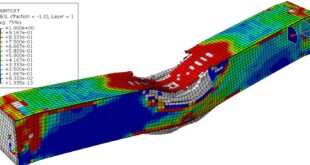

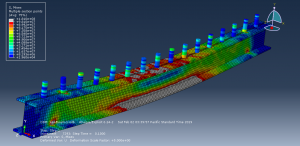

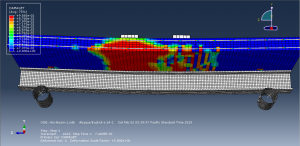

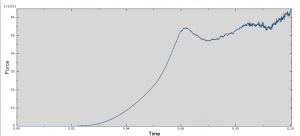

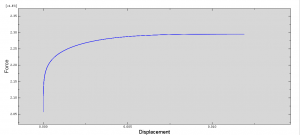

Elastic plastic material for aluminium and steel ,concrete damage plasticity model (CDP) for concrete has used. Dynamic explicit procedure is appropriate because of the complicity and many contacts which causes unconvergences in the static analysis. During the analysis and after applying bending load as concentrated force to the two rigid body as pushers, the tensile and compressive damage on the concrete slab is obvious. The beam and the steel connectors experienced a huge stress which you can see some results of this simulation at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials