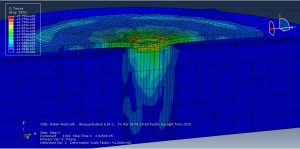

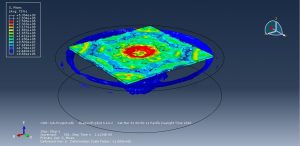

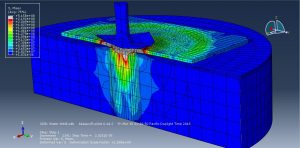

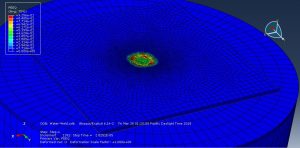

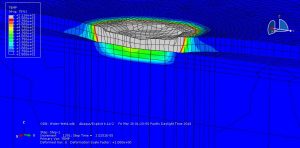

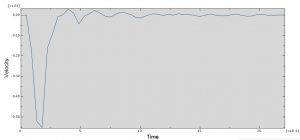

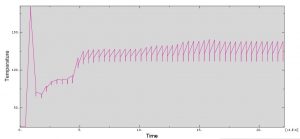

To gain an understanding of the mechanism of material damage and removal during high-speed liquid impact and understanding of the magnitude and spatial distribution of the transient pressures caused by such an impact on a solid surface would be helpful.The water jet spot welding tests were preformed using a Abaqus software. This consisted essentially of a water column and a 4.2mm diameter nozzle. Target blocks of aluminium polished 50mm×۵۰mm×۱mm cladding plates of aluminium was used in the tests. The separation distance between the target and flyer plate varied between 0.5 .All parts are modeled as three dimensional and deformable. To model water behavior Us-Up equation and Lagrangian method has been applied. Johnson-Cook material model is used to definite aluminium plates material. Dynamic-Temp Explicit is appropriate for this analysis and proper boundary and interaction has been implanted. During water jet impact, flyer plate moved toward the base plate and after contact small joint was crated between two plates. You can see some figures of this simulation at below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Two Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials