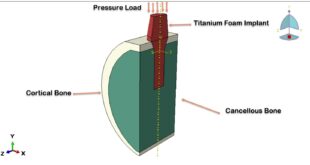

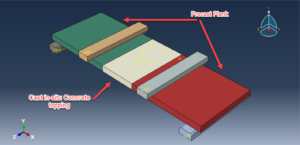

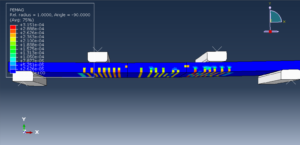

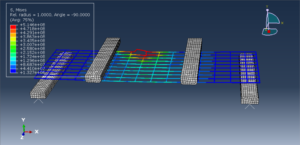

This tutorial investigates the Simulation behavior of a new type of reinforced concrete composite slab with a joint in Abaqus. The precast plank concrete and in-situ concrete topping are modeled as three-dimensional solid parts. The steel reinforcements are modeled as wire parts. You can see a figure of the assembled parts below

Precast concrete (PC) structures can be seen in buildings throughout the world due to their advantages of better construction quality, lower labor costs, and shorter construction times. Composite slab, as one of the most commonly used elements in floor systems of PC residential buildings, is formed by bottom precast planks and a cast-in-situ concrete topping. To improve the flexural stiffness of the bottom precast plank and increase the bonding performance between the precast plank and the cast-in-situ concrete topping, lattice girders are usually installed in the precast plank. However, due to the limitation of the thickness of the composite slab with lattice girders used in China, the height of the lattice girder is usually small. As a result, the improvement in stiffness of the precast plank by the lattice girder is limited, which requires the erection of vertical supports during the construction process, increasing the construction cost and prolonging the construction period

Composite slabs, consisting of a precast plank and a cast-in-situ concrete topping, are the most commonly used horizontal structural components in prefabricated buildings. To solve the problem that the precast plank of the composite slab is easy to crack and a lot of vertical supports are needed in its construction, this study proposes a new type of composite slab with a joint. The precast plank of this novel composite slab is fully prefabricated in the midspan area, and concrete is poured on-site only at the surrounding joints.

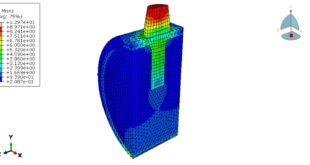

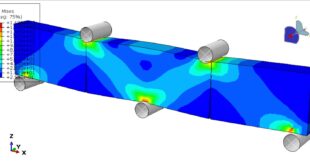

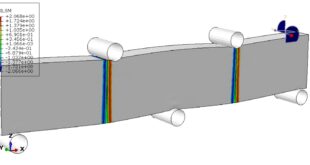

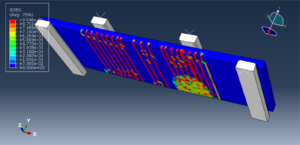

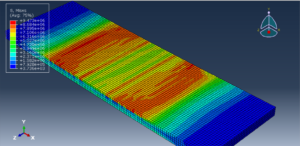

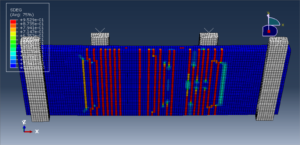

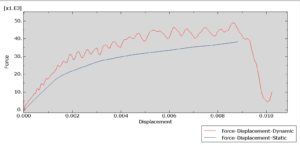

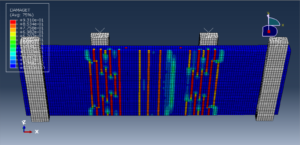

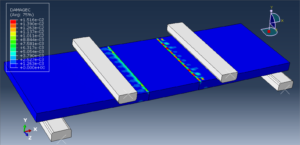

All the details of modeling and simulation are explained in the tutorial video. After the four-bending test simulation in both static and dynamic methods, all results such as stress, strain, tension and compression damage, force-displacement diagram, and others are available. You can see some figures of the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials