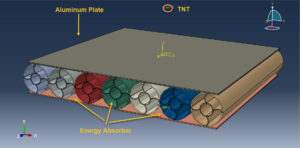

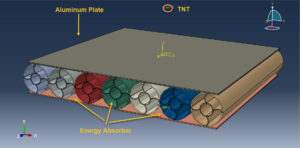

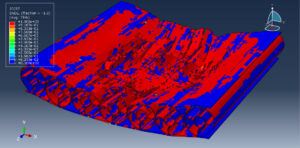

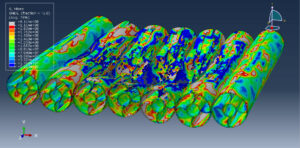

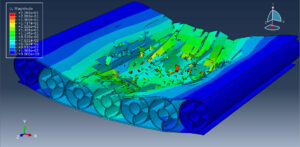

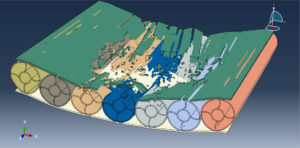

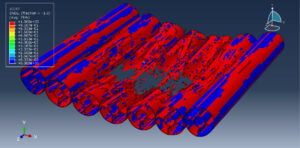

In this tutorial, the simulation air blast load over an aluminum sandwich structure with inner energy absorbers in Abaqus was studied. The two upper and bottom aluminum plates are modeled as dimensional shell parts. The inner energy absorbers are also modeled as three-dimensional parts. You can see a figure of the assembled parts below

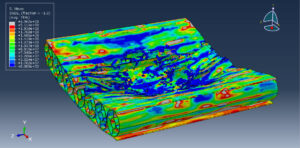

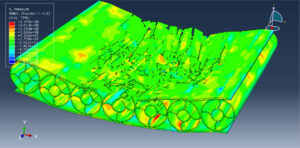

Aluminum structures are the perfect material for energy absorption applications due to their high strength-to-weight ratio. They are also excellently resistant to moisture and corrosion. Another advantage of using aluminum structures for energy absorption is their ability to absorb forces over a large area. To model aluminum behavior under severe blast load, the Johnson-Cook hardening and dynamic damage failure is considered.

The Johnson-Cook model is a plasticity and failure model applied to metal structures. Due to its simple form and a small number of unknown parameters, it is widely used in engineering. For materials without given parameters in the handbook, core parameters need to be obtained through parameter fitting of test data.

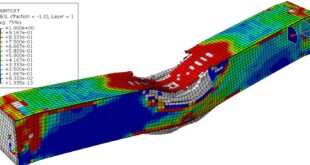

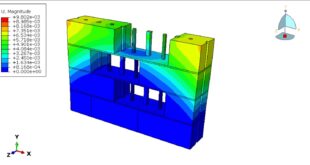

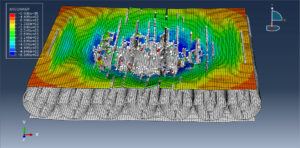

Dynamic explicit step and general contact capability are appropriate for this type of explosion. The proper boundary conditions and meshes are applied to all parts. After the analysis, all results such as damage, failure, stress, strain, explosion pressure, forces, and other results are available. You can see some figures of the results below

You can provide this simulation’s CAE, INP, and English video files here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to begin the process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment, send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials