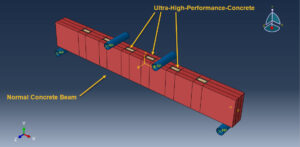

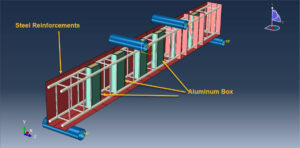

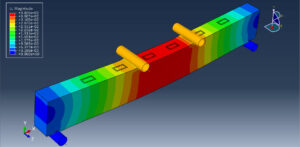

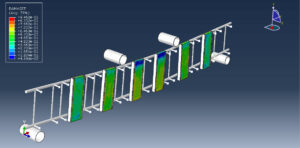

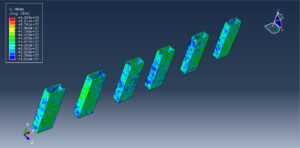

In this tutorial, the ُSimulation of defected RC beam with sustainable aluminum boxes incorporating ultra-high-performance concrete in Abaqus has been investigated. The concrete beam, UHPC members, and aluminum boxes are modeled as three-dimensional solid parts. The steel reinforcements are modeled as wire parts. You can see figures of the assembled parts below

Building codes require shear reinforcement in concrete beams to prevent catastrophic and sudden shear failure. However, many existing beams might lack adequate reinforcement for various reasons, leaving them susceptible to this brittle failure mode. Consequently, repair or strengthening becomes crucial to restore their structural integrity and safety. RC beams can be strengthened through various techniques, each offering advantages and limitations. The externally bonded (EB) method, which involves bonding external steel plates or fiber-reinforced polymer (FRP) laminates/sheets to the beam’s surface to enhance its flexural and shear capacity, has been explored in several studies

While traditional methods exist for strengthening RC beams, their sustainability is concerning. Aluminum, with its eco-friendly attributes, presents itself as a promising alternative. However, research on using sustainable aluminum boxes and HPCs for shear strengthening of RC beams is scarce. Existing research mainly focuses on aluminum plates for flexural strengthening, highlighting issues like debonding and neglecting the potential of aluminum boxes. Furthermore, the combined application of aluminum and HPCs for shear strengthening remains unexplored. Addressing these gaps by investigating bonding mechanisms, shear performance, and compatibility with HPC is crucial for developing a sustainable and effective solution for shear-strengthening RC beams. This research gap presents a significant opportunity to contribute to the field of sustainable RC beam strengthening.

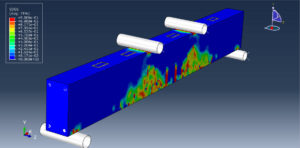

To model normal and UHPC concrete in this simulation, the Concrete Damaged Plasticity model is selected. The model is a continuum, plasticity-based, damage model for concrete. It assumes that the main two failure mechanisms are tensile cracking and compressive crushing of the concrete material. To model aluminum and steel members’ material data, the elastic-plastic model is considered

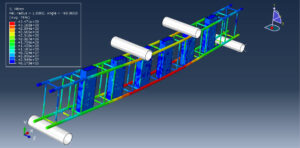

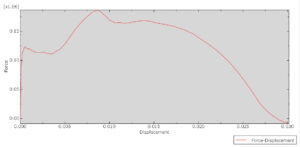

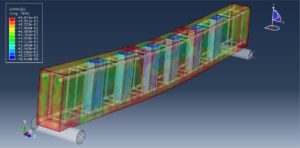

Both general static and dynamic steps are used to make a compression between the two methods. The proper interaction, constraints, loads, boundary conditions, and meshes are assigned to all parts

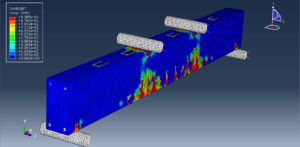

After the analysis, all results such as stress, strain, tension and compression damage, force-displacement diagram, and others are available. You can see some figures of the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials