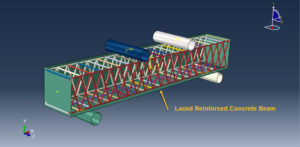

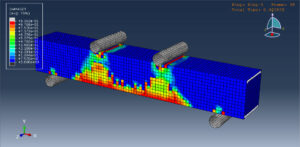

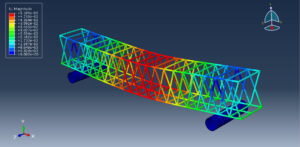

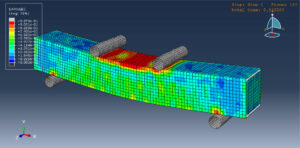

Simulation of Flexural Behavior of Laced Reinforced Concrete Beam in Abaqus has been investigated in the present study. The concrete beam is modeled as a three-dimensional solid part. The laced steel reinforcements are modeled as three-dimensional wire parts. The hydraulic jacks are modeled as rigid parts. You can see a figure of the assembled parts below

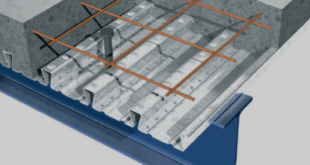

In reinforced concrete structures, beams are elements that are designed to sustain transverse loads. Deep beams are two-dimensional elements because of the high ratio of depth to length. Therefore, the cross-sections exhibit nonlinear deformations under bending resulting in nonlinearity in the distribution of strains across these sections. Thus, shear deformations are remarkable compared to pure flexural ones. Consequently, shear is the governing criterion in the design of deep beams .On the other hand, ordinary shallow beams are one-dimensional elements, in which the strains are almost distributed linearly across the section. In general, they experience ductile flexure failure due to their low flexural strength compared to shear strength. In reinforced concrete moderately deep (RCMD) beams, flexural strength is close to or equal to shear strength. Therefore, these beams undergo flexural-shear failure. Moderately deep beams are frequently used in tall buildings, silos, shopping malls, and offshore structures.Lacings comprise continuous bent bars tying the longitudinal flexural bars on both sides of laced reinforced concrete (LRC) elements.Lacings were found to be effective in improving the ductility of reinforced concrete elements by getting significant support rotation, attaining strain hardening after yield, restricting concrete spalling, and increasing the shear strength under blast loading

In order to study the behavior of laced moderately deep beams subjected to monotonic loading in more detail, a numerical investigation using the FE package ABAQUS was adopted.ABAQUS is capable of precisely simulating the nonlinear behavior of reinforced concrete elements. Unlike steel, concrete exhibits a completely different behavior in compression and tension. To take this phenomenon into accounts, ABAQUS supposes a concrete damage plasticity model (CDPM), which effectively defines the two failure mechanisms, namely cracking and crushing, that take place in concrete

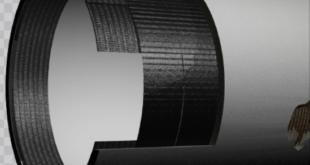

Both static and dynamic approach were used to demonstrate their capabilities. The proper interactions and boundary are assigned to parts. The mesh should fine to obtain the correct resutls

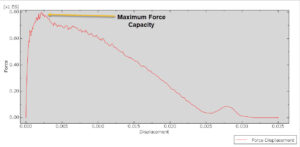

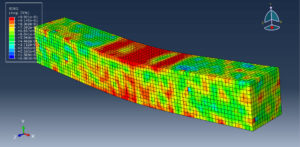

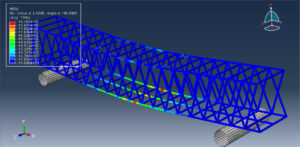

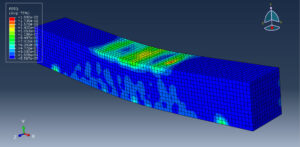

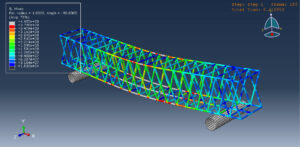

After the simulation, all results such as stress, strain, tension and compression damage, force-displacement diagram, and others are available. You can see some figures for the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials