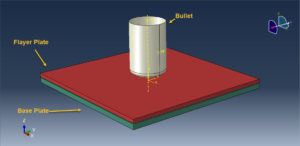

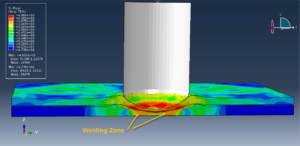

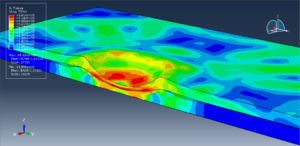

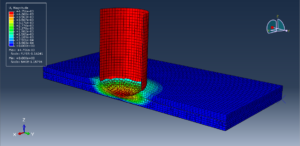

In this tutorial, the Simulation inpact spot welding of two steel plates in Abaqus has been done. The steel flyer and base plates are modeled as three-dimensional solid part. The rigid impactor is modeled as three-dimensional shell part. You can see a figure of the assembled parts below

Due to the human need to combine different metal parts, the welding process has always been the focus of scientists. During the welding process, the bound-aries are removed and the materials are bonded together. Traditional methods of welding alter the microstructural and mechanical properties of the base materials due to different heat cycles and addi-tionally, it leads to problems such as loss of softness, hot and cold cracking, formation of harmful phases, and reduced corrosion resistance. These problems are more likely to occur in nonhomogenous welding due to differences in physical properties such as melting point. Therefore, solid-state welding processes are a reliable alternative for bonding nonhomogeneous materials since there is no need for extensive melting of materials to bond. Recently, various solid-state welding methods such as magnetic pulse welding, laser impact welding, ultrasonic welding, friction stir welding, and projectile impact spot welding have made significant progress. High-speed impact welding is known for its low welding temperature and high welding velocity. The ISW process is one of the high-speed impact welding methods in which a high-velocity projectile was used to impact the plates to create an atomic bonding. Based on the aforemen-tioned points, it was found that impact welding includes a wide range of research in mechanics, heat transfer, and materials

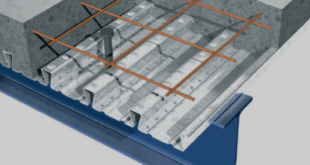

The Johnson-Cook plasticity and damage is selceted for the steel material. The Johnson-Cook plasticity model is a particular type of Mises plasticity model with analytical forms of the hardening law and rate dependence, suitable for high-strain-rate deformation of many materials, including most metals. The data are extracted from the paper for the JC model. The dynamic explicit step is appropraite for this type of analysis. The srface to surface contact is consider between rigid projectile and flyer plate. The surface to surface contact with specific contact property is selected for the flyer and base plate. The fixed boundary condition is assined to the outer sides of the plates and initial velocity to the projectile. The mesh should be fine to obtain correct results

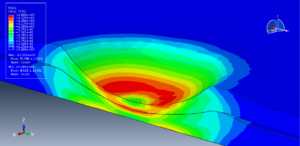

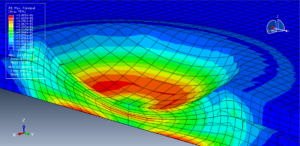

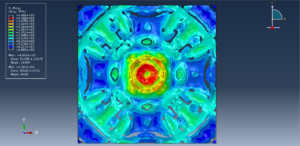

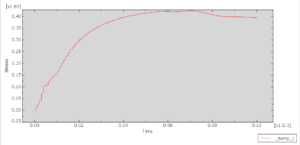

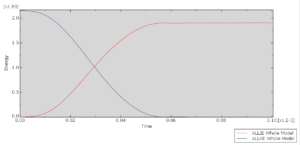

After the simulation, all results such as stress, strain, contact zone,… are available. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials