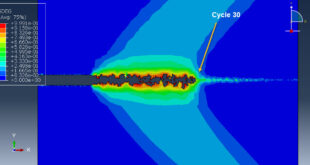

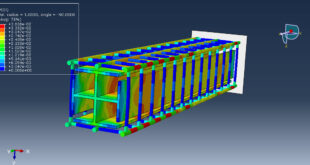

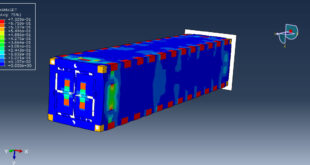

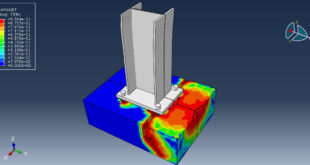

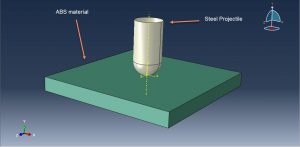

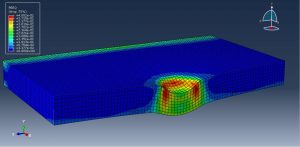

In this tutorial, the Simulation steel projectile impact on the Acrylonitrile butadiene styrene(ABS) plate in Abaqus has been investigated. Polymers are often used in applications where impact resistance is required. In this context, specific polymers such as ABS (acrylonitrile butadiene styrene) have been created with rubber particles in order to increase the toughness. The particles act as craze stabilizers, thereby delaying crack initiation and increasing the strain to failure. The deformation of a structural component or a tensile sample during characterization tests can be accompanied by intense strain localization and more or fewer temperature variations, depending mainly on the material and strain rates. The steel projectile is modeled as a three-dimensional shell part. The ABS plate is modeled as a three-dimensional solid part. You can see a figure of the assembled parts below

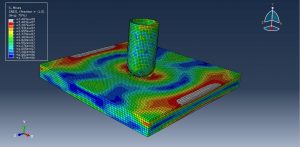

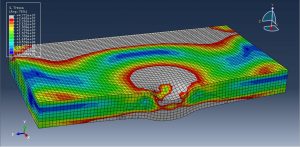

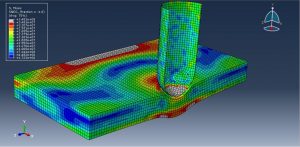

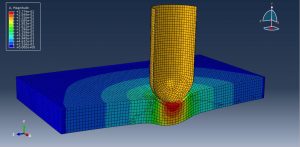

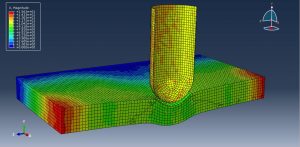

To model projectile behavior, steel material with elastic and Johnson-Cook plasticity is used. This hardening model is suitable for rapid and large deformation. To model ABS material behavior, elasticity and Johson-Cook plasticity are implied. The dynamic explicit step is appropriate for this type of analysis. The surface to surface contact with friction as an interaction property is selected. The fixed boundary condition is assigned to the two sides of the target and initial velocity to the steel projectile. The mesh should be fine to obtain the good and correct result

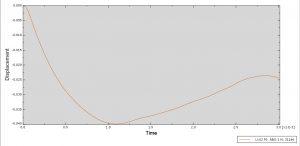

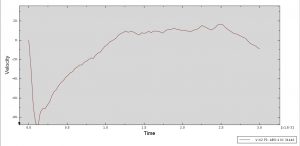

After the simulation, all results such as stress, strain, compression,…are achievable. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Three Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials