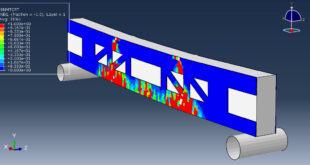

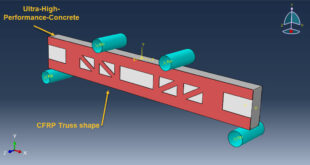

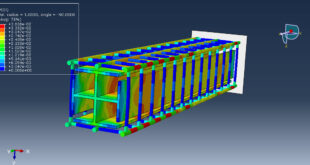

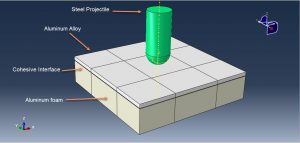

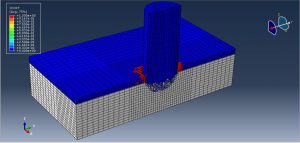

In this tutorial, the Simulation Steel bullet impact on the composite panel(Aluminum-Epoxy glue-Aluminum Foam) in Abaqus has been investigated. The steel bullet is modeled as a three-dimensional solid part. The aluminum sheet, Epoxy glue, and aluminum foam are modeled as three-dimensional solid parts. You can see a figure of the assembled parts at below

Currently, the usage of sandwich structures with a metal foam core is seeing increasing usage in different applications. From a structural point of view, in a sandwich structure, with metallic sheets and metallic foam core, the foam is responsible for absorbing large amounts of energy when the structure is being plastically deformed. The foam core also provides good insulation to vibrations and contributes to the weight reduction of the. structure. As a result, these materials are widely used in high-technology industries, such as the automotive and aerospatial industries. The aluminum foam material is modeled as Crushablefoam plasticity in Abaqus. The isotropic plasticity with stress-strain hardening is used. The steel material is used for the bullet as a elastic-plastic material with Johnson-Cook damage criteria. The glue or cohesive interface is modeled as an elastic material type traction with damage criteria. The aluminum face sheet is modeled as an elastic-plastic material with Johnson-Cook damage criteria to predict the failure zone. The dynamic explicit procedure is used to model the impact phenomena. The surface to surface contact with contact property as a friction coefficient is used between the bullet and aluminum sheet. The general contact algorithm with contact property is used to consider all contacts of the parts. The contact between aluminum sheet and glue, the aluminum foam and glue are considered as a perfect contact. The fixed boundary condition is assigned to the side surfaces of the panel. The initial velocity is applied to the steel bullet. The mesh should be fine to achieve good results

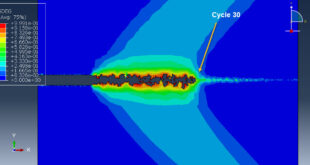

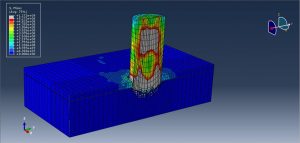

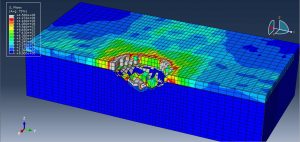

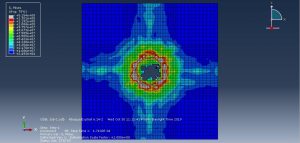

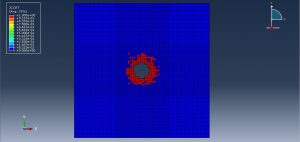

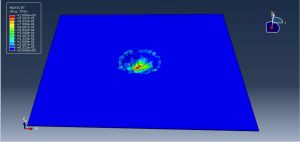

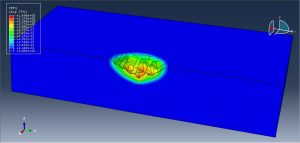

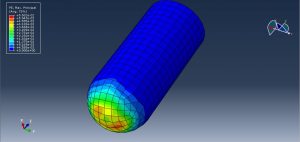

After the simulation all results such as stress, strain, damage and failure zone, aluminum foam compression…. are obtainable. You can see some figures for the results below

You can provide CAE ,INP,and English video files of this simulation here. The cost of these files is Twenty-Six Euros. you can click on the bellow bottom to beginning process

You can purchase the tutorial through a PayPal account, a Visa, or a Master card, just before payment,send me an email to this address: karampourp@gmail.com

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials