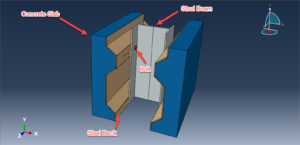

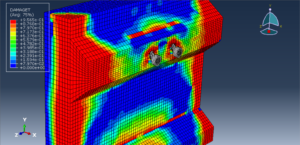

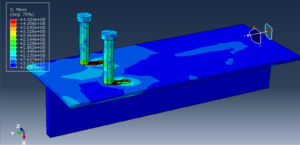

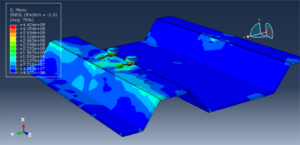

In this tutorial, the ُSimulation of the behavior of bolted shear connectors in composite slabs with steel deck in Abaqus has been studied. The steel beam, concrete, and bolts are modeled as a three-dimensional solid part. The steel deck is modeled as a shell part. You can see a figure of the assembled parts below

Over the past few years, more concerns related to the building environments have been greatly addressed to enhance the current building environment and empower future generations to benefit from an ideal life and adequate resources to meet their needs. These concerns include sustainability, energy conservation, construction members, building deconstruction systems, and recycling/reusing building materials. As far as we know, construction significantly affects the living environment, in particular,r the management and demolition of building structures after their intended design service life. The steel-concrete composite structures are widely used nowadays

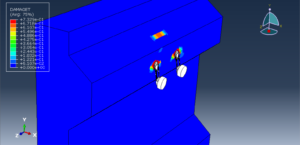

in bridges and high-rise buildings. For achieving the composite action between the composite concrete slabs and steel beams, the welded shear connectors are used in many composite systems due to their shear loading resistance. Consequently, such welded shear connectors make it almost impossible to dismantle, alternate, and deconstruct the composite structures after their design service life

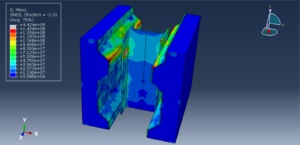

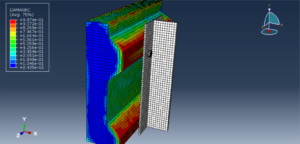

To steel behavior under large deformation, Johnson-Cook hardening and damage are selected. The concrete damaged plasticity is a good material model for concrete

Dynamic explicit step with mass scale technique is selected for this analysis. All contacts as surface-to-surface contact with contact property are applied. The proper boundaries and meshes are assigned to all parts.

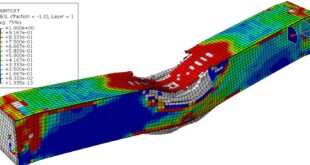

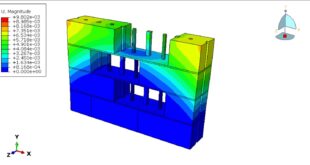

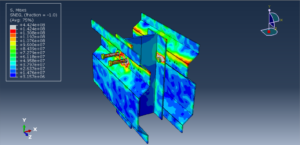

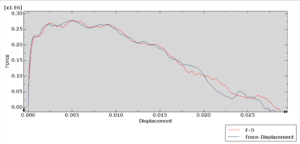

After the simulation, all results such as stress, strain, tensile damage, bolt failure, force-displacement diagram, and others are available. You can see some figures of the results below

Abaqus tutorials Abaqus tutorials

Abaqus tutorials Abaqus tutorials